Microbial contamination of jet fuel is problematic as it can lead to spoilage of stored fuels, biocorrosion, filter blocking and biofouling. Aircraft are monitored routinely for microbial growth and, if severely affected, are withdrawn from service for decontamination at a significant economic cost.

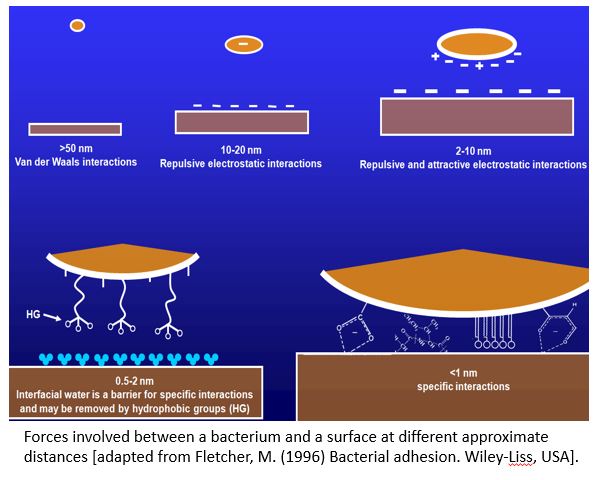

Microbes attach readily to the different material surfaces found in the aviation fuel supply chain and form communities known as “biofilms”. Biofilms have a protective role, buffering the microbial communities from the harsh environmental conditions inside fuel systems and allowing them to remain in place as fuel is used and replenished. Over time these communities can develop to such an extent that they may corrode underlying surfaces, lead to inaccurate gauge readings or detach and block filters.

Microbial growth in aviation systems is inevitable. The fuel acts as a rich energy supply and the ingress of water cannot be avoided. Routine draining of water and good housekeeping reduces microbial growth, but it cannot be avoided completely.

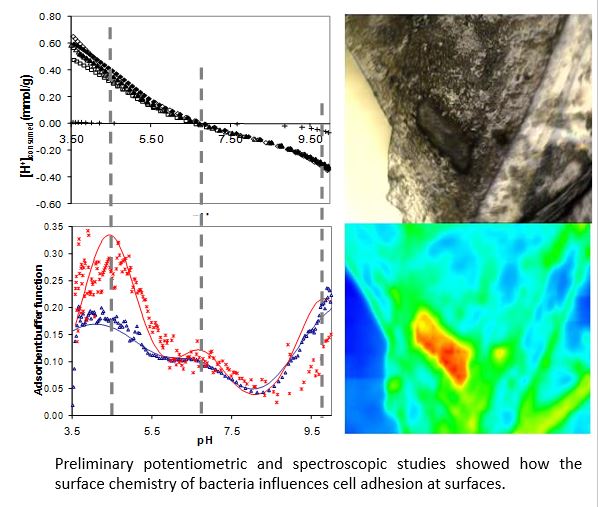

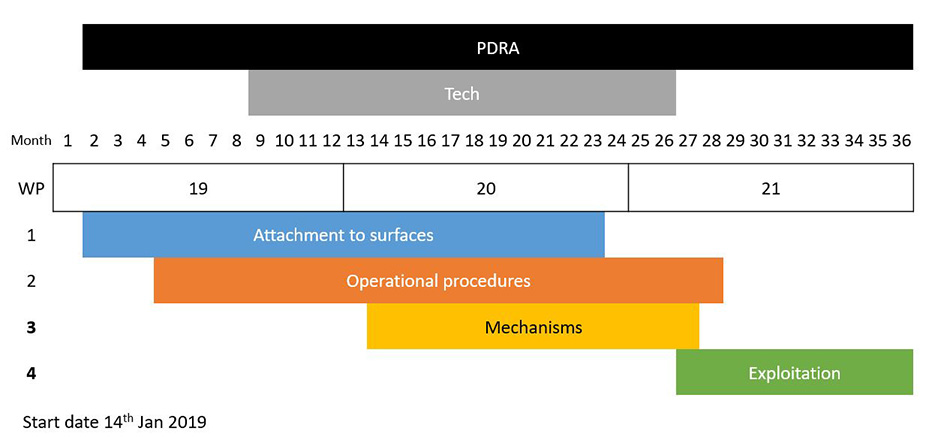

Co-funded by InnovateUK, this work package (4.3) is a collaboration between Airbus, Conidia and researchers at the University of Sheffield and Swansea University, that seeks to develop a mechanistic understanding of microbial biofilm development in current and future aviation systems, to either minimise biofilm development and/or facilitate biofilm removal from contaminated surfaces.