Abbas, B., Jewell, E., Lau, Y., Searle, J., & Claypole, T. (2023). Photonic sintering of copper for rapid processing of thick film conducting circuits on FTO coated glass. Scientific Reports, 13,5080

Ahmed, H., Bedding-Tyrrell, M., Deganello, D., Xia, Z., Xiong, Y., & Zhao, F. (2023). Efficient calculation of fluid-induced wall shear stress within tissue engineering scaffolds by an empirical model. Medicine in Novel Technology and Devices, 18, 100223

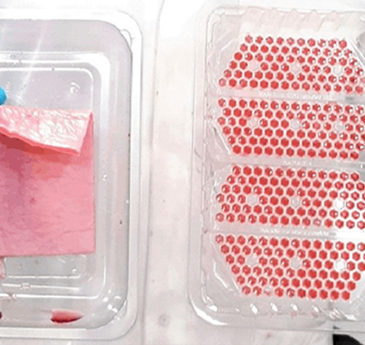

Alaizoki, A., Phillips, C., Hardwick, C., Parker, D., & Deganello, D. (2022). Enhanced liquid retention capacity within plastic food packaging through modified capillary recesses. Journal of Food Engineering, 323, 111010

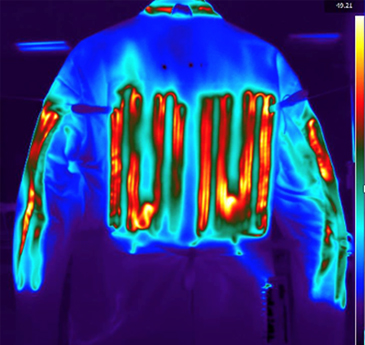

Claypole, A., Claypole, J., Leeder, J., Stevens, G., Johnson, F., Bezodis, N., Parker, M., Claypole, T., Gethin, D., & Kilduff, L. (2022). Large area, stretchable, wearable, screen-printed carbon heaters for use in elite sport. Journal of Coatings Technology and Research, 20

Claypole, A., Claypole, J., Bezodis, N., Kilduff, L., Gethin, D., & Claypole, T. (2022). Printed Nanocarbon Heaters for Stretchable Sport and Leisure Garments. Materials, 15(2), 573

Alaizoki, A., Phillips, C., Parker, D., Hardwick, C., McGettrick, J., & Deganello, D. (2022). Improvement in liquid absorption of open-cell polymeric foam by plasma treatment for food packaging applications. Journal of Applied Polymer Science, 139(17), 52015

de Boode, B., Phillips, C., Lau, J., Adomkevicius, A., McGettrick, J., & Deganello, D. (2022). Glassy carbon manufacture using rapid photonic curing. Journal of Materials Science, 57(1), 299-310.

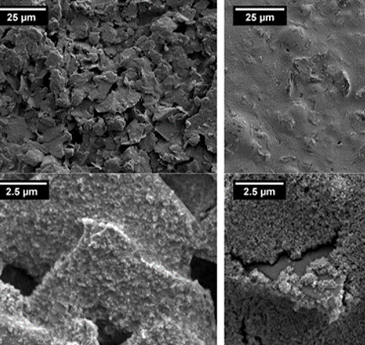

Potts, S., Korochkina, T., Holder, A., Jewell, E., Phillips, C., & Claypole, T. (2022). The influence of carbon morphologies and concentrations on the rheology and electrical performance of screen-printed carbon pastes. Journal of Materials Science, 57(4), 2650-2666.

Ippolito, F., Hübner, G., Claypole, T., & Gane, P. (2021). Calcium Carbonate as Functional Filler in Polyamide 12-Manipulation of the Thermal and Mechanical Properties. Processes, 9(6), 937

Alaizoki, A., Phillips, C., Parker, D., Hardwick, C., Griffiths, C., & Deganello, D. (2021). Effect of plasma treatment on improving liquid retention capacity of capillary recesses for food packaging applications. Food Packaging and Shelf Life, 30, 100759

Spieser, H., Jardin, A., Deganello, D., Gethin, D., Bras, J., & Denneulin, A. (2021). Rheology of cellulose nanofibrils and silver nanowires for the development of screen-printed antibacterial surfaces. Journal of Materials Science, 56(21), 12524-12538.

Ippolito, F., Hübner, G., Claypole, T., & Gane, P. (2021). Impact of Bimodal Particle Size Distribution Ratio of Functional Calcium Carbonate Filler on Thermal and Flowability Properties of Polyamide 12. Applied Sciences, 11(2), 641

Claypole, A., Claypole, J., Kilduff, L., Gethin, D., & Claypole, T. (2021). Stretchable Carbon and Silver Inks for Wearable Applications. Nanomaterials, 11(5), 1200

Spieser, H., Tehrani, Z., Ali, M., Daghigh Ahmadi, E., Denneulin, A., Bras, J., Deganello, D., & Gethin, D. (2021). Metal organic framework sensors on flexible substrate for ammonia sensing application at room temperature. Journal of Materials Chemistry C(19), 6332-6343.

Claypole, A., Claypole, J., Claypole, T., Gethin, D., & Kilduff, L. (2021). The effect of plasma functionalization on the print performance and time stability of graphite nanoplatelet electrically conducting inks. Journal of Coatings Technology and Research, 18(1), 193-203.

Menéndez, M., Martinez, A., Sánchez, P., Gomez, D., Andrés, L., Haponow, L., Bristow, N., Kettle, J., Korochkina, T., & Gethin, D. (2020). Development of intermediate layer systems for direct deposition of thin film solar cells onto low cost steel substrates. Solar Energy, 208, 738-746.

Shi, Y., He, R., Deng, X., Shao, Z., Deganello, D., Yan, C., & Xia, Z. (2020). Three-dimensional biofabrication of an aragonite-enriched self-hardening bone graft substitute and assessment of its osteogenicity in vitro and in vivo. Biomaterials Translational, 1(1), 69-81.

Wang, L., Zhang, W., Samavat, S., Deganello, D., & Teng, V. (2020). Vertically Aligned Graphene Prepared by Photonic Annealing for Ultrasensitive Biosensors. ACS Applied Materials & Interfaces, 12(31), 35328-35336.

Assaifan, A., Alshehri, N., Lewis, A., Samavat, S., Lau, J., Deganello, D., & Teng, V. (2020). Effect of intense pulsed light on hydrothermally grown ZnO nanowires. Materials Letters, 271, 127797

Spieser, H., Denneulin, A., Deganello, D., Gethin, D., Koppolu, R., & Bras, J. (2020). Cellulose nanofibrils and silver nanowires active coatings for the development of antibacterial packaging surfaces. Carbohydrate Polymers, 240, 116305

Clifford, B., Phillips, C., & Deganello, D. (2020). Optimisation of aerosol jet deposition for high-resolution selective patterning of silver tracks. Journal of Print and Media Technology Research, 9(1), 21-29.

Tehrani, Z., Whelan, S., Mostert, B., Paulin, J., Ali, M., Daghigh Ahmadi, E., Graeff, C., Guy, O., & Gethin, D. (2020). Printable and flexible graphene pH sensors utilising thin film melanin for physiological applications. 2D Materials, 7(2), 024008

Rassek, P., Steiner, E., Herrenbauer, M., & Claypole, T. (2020). Gap width modification on fully screen-printed coplanar Zn|MnO2 batteries. Flexible and Printed Electronics, 5(3), 035007

Potts, S., Phillips, C., Claypole, T., & Jewell, E. (2020). The Effect of Carbon Ink Rheology on Ink Separation Mechanisms in Screen-Printing. Coatings, 10(10), 1008

Rassek, P., Steiner, E., Claypole, T., Krebs, M., & Herrenbauer, M. (2020). Passivation capability of carbon black layers for screen-printed battery applications with Ag current collectors. Applied Physics A, 126(8)

Claypole, A., Claypole, J., Holder, A., Claypole, T., & Kilduff, L. (2020). Rheology of high-aspect-ratio nanocarbons dispersed in a low-viscosity fluid. Journal of Coatings Technology and Research, 17(4), 1003-1012.

Ippolito, F., Hübner, G., Claypole, T., Gane, P., & Claypole, T. (2020). Influence of the Surface Modification of Calcium Carbonate on Polyamide 12 Composites. Polymers, 12(6), 1295

Potts, S., Phillips, C., Jewell, E., Clifford, B., Lau, Y., & Claypole, T. (2020). High-speed imaging the effect of snap-off distance and squeegee speed on the ink transfer mechanism of screen-printed carbon pastes. Journal of Coatings Technology and Research, 17(2), 447-459.

Ippolito, F., Rentsch, S., Hübner, G., Claypole, T., & Gane, P. (2019). Influence of calcium carbonate on polyamide 12 regarding melting, formability and crystallization properties. Composites Part B: Engineering, 164, 158-167.

Potts, S., Lau, Y., Dunlop, T., Claypole, T., Phillips, C., Claypole, T., & Phillips, C. (2019). Effect of photonic flash annealing with subsequent compression rolling on the topography, microstructure and electrical performance of carbon-based inks. Journal of Materials Science, 54(11), 8163-8176.

Rassek, P., Steiner, E., Herrenbauer, M., & Claypole, T. (2019). The effect of electrode calendering on the performance of fully printed Zn∣MnO2 batteries. Flexible and Printed Electronics, 4(3), 035003

Jalalian-Khakshour, A., Phillips, C., Jackson, L., Dunlop, T., Margadonna, S., & Deganello, D. (2019). Solid-state synthesis of NASICON (Na3Zr2Si2PO12) using nanoparticle precursors for optimisation of ionic conductivity. Journal of Materials Science, 55, 2291-2302.

Morgan, M., Curtis, D., & Deganello, D. (2019). Control of morphological and electrical properties of flexographic printed electronics through tailored ink rheology. Organic Electronics, 73, 212-218.

Mazzali, F., Orzech, M., Adomkevicius, A., Pisanu, A., Malavasi, L., Deganello, D., & Margadonna, S. (2019). Designing a High-Power Sodium-Ion Battery by in Situ Metal Plating. ACS Applied Energy Materials, 2(1), 344-353.

Allen, G., Griffin, S., Clifford, B., Phillips, C., Van Keulen, G., (2019). Development of bio-inspired protein-based materials as novel transparent adhesives for glass laminates. Access Microbiology, 1(1A)

Carey, T., Jones, C., Le Moal, F., Deganello, D., & Torrisi, F. (2018). Spray-Coating Thin Films on Three-Dimensional Surfaces for a Semitransparent Capacitive-Touch Device. ACS Applied Materials & Interfaces, 10(23), 19948-19956.

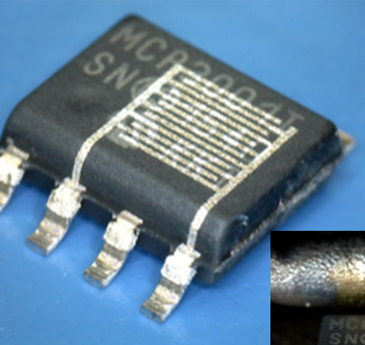

Clifford, B., Beynon, D., Phillips, C., & Deganello, D. (2018). Printed-Sensor-on-Chip devices – Aerosol jet deposition of thin film relative humidity sensors onto packaged integrated circuits. Sensors and Actuators B: Chemical, 255(1), 1031-1038.

Holder, A., Claypole, J., Claypole, T., Cooper, P., Williams, R., & Curtis, D. (2018). Fourier Transform Controlled Stress Parallel Superposition (FT-CSPS): Validation and application in processing printable functional materials. Physics of Fluids, 30(7), 077105

Morgan, M., Holder, A., Curtis, D., & Deganello, D. (2018). Formulation, characterisation and flexographic printing of novel Boger fluids to assess the effects of ink elasticity on print uniformity. Rheologica Acta, 57(2), 105-112.

Hughes, L., Bristow, N., Korochkina, T., Sanchez, P., Gomez, D., Kettle, J., & Gethin, D. (2018). Assessing the potential of steel as a substrate for building integrated photovoltaic applications. Applied Energy, 229, 209-223.

Radley, E., Lowe, C., & Gethin, D. (2018). Stress Whitening in Polyester Melamine Coatings. Johnson Matthey Technology Review, 62(3), 341-349.

Abid, H., Johnson, D., Clifford, B., Gethin, D., Bertoncello, P., Hashaikeh, R., & Hilal, N. (2018). Periodic electrolysis technique for in situ fouling control and removal with low-pressure membrane filtration. Desalination, 433, 10-24.

Abid, H., Johnson, D., Clifford, B., Gethin, D., Bertoncello, P., Hashaikeh, R., & Hilal, N. (2018). Periodic electrolysis technique for in situ fouling control and removal with low-pressure membrane filtration. Desalination, 433, 10-24.

Phillips, C., Al-Ahmadi, A., Potts, S., Claypole, T., Deganello, D., (2017). The effect of graphite and carbon black ratios on conductive ink performance. Journal of Materials Science, 52(16), 9520-9530.

Fung, C., Lloyd, J., Samavat, S., Deganello, D., Teng, K., Teng, V., & Deganello, D. (2017). Facile fabrication of electrochemical ZnO nanowire glucose biosensor using roll to roll printing technique. Sensors and Actuators B: Chemical, 247, 807-813.

Thomas, D., McCall, C., Tehrani, Z., Claypole, T., & Claypole, T. (2017). Three-Dimensional–Printed Laboratory-on-a-Chip With Microelectronics and Silicon Integration. Point of Care: The Journal of Near-Patient Testing & Technology, 16(2), 97-101.

Baker, J., Worsley, C., Lee, H., Clark, R., Tsoi, W., Williams, G., Worsley, D., Gethin, D., Watson, T., (2017). Development of Graphene Nano-Platelet Ink for High Voltage Flexible Dye Sensitized Solar Cells with Cobalt Complex Electrolytes. Advanced Engineering Materials

Abid, H., Lalia, B., Bertoncello, P., Hashaikeh, R., Clifford, B., Gethin, D., & Hilal, N. (2017). Electrically conductive spacers for self-cleaning membrane surfaces via periodic electrolysis. Desalination, 416, 16-23.

Mouhamad, Y., Mortensen, T., Holder, A., Lewis, A., Maffeis, T., & Deganello, D. (2016). High performance tunable piezoresistive pressure sensor based on direct contact between printed graphene nanoplatelet composite layers. RSC Advances, 6(107), 105206-105210.

Assaifan, A., Lloyd, J., Samavat, S., Deganello, D., Stanton, R., & Teng, V. (2016). Nanotextured Surface on Flexographic Printed ZnO Thin Films for Low-Cost Non-Faradaic Biosensors. ACS Applied Materials & Interfaces, 8(49), 33802-33810.

Mogg, B., Deganello, D., Claypole, T., & Phillips, C. (2016). Flexographic printing of ultra-thin semiconductor polymer layers. Translational Materials Research, 3(1), 015001

Tomašegović, T., Beynon, D., Claypole, T., Poljaček, S., & Claypole, T. (2016). Tailoring the properties of deposited thin coating and print features in flexography by application of UV-ozone treatment. Journal of Coatings Technology and Research, 13(5), 815-828.

Tehrani, Z., Thomas, D., Korochkina, T., Phillips, C., Lupo, D., Lehtimäki, S., O'Mahony, J., Gethin, D (2016). Large-area printed supercapacitor technology for low-cost domestic green energy storage. Energy

Tehrani, Z., Nordli, H., Pukstad, B., Gethin, D., & Chinga-Carrasco, G. (2016). Translucent and ductile nanocellulose-PEG bionanocomposites—A novel substrate with potential to be functionalized by printing for wound dressing applications. Industrial Crops and Products, 93, 193-202.

Malik, T., Malik, F., Clement, R., Gethin, D., Kiernan, M., Goral, T., Griffiths, P., Beynon, D., Parker, A., Gethin, D., Clement, M., & Beynon, D. (2016). Hierarchical structures of cactus spines that aid in the directional movement of dew droplets. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 374(2073), 20160110

Kettle, J., Bristow, N., Moudam, O., Li, B., Katz, E., Benatto, G., Krebs, F., Gethin, D., & Tehrani, Z. (2016). Printable luminescent down shifter for enhancing efficiency and stability of organic photovoltaics. Solar Energy Materials and Solar Cells, 144, 481-487.

Baker, J., McGettrick, J., Gethin, D., Watson, T., Gethin, D., Watson, T., McGettrick, J., & Baker, J. (2015). Impedance Characteristics of Transparent GNP-Pt Ink Catalysts for Flexible Dye Sensitized Solar Cells. Journal of the Electrochemical Society, 162(8), H564-H569.

Powell, L., Rees, A., Powell, L., Chinga-Carrasco, G., Gethin, D., Syverud, K., Hill, K., & Thomas, D. (2015). 3D Bioprinting of Carboxymethylated-Periodate Oxidized Nanocellulose Constructs for Wound Dressing Applications. BioMed Research International, 2015, 1-7.

Giannetti, C., Ransing, M., Ransing, R., Bould, D., Gethin, D., & Sienz, J. (2015). Organisational Knowledge Management for Defect Reduction and Sustainable Development in Foundries. International Journal of Knowledge and Systems Science, 6(3), 18-37.

Tehrani, Z., Korochkina, T., Govindarajan, S., Thomas, D., O’Mahony, J., Kettle, J., Claypole, T., & Gethin, D. (2015). Ultra-thin flexible screen printed rechargeable polymer battery for wearable electronic applications. Organic Electronics, 26, 386-394.

Jewell, E., Hamblyn, S., Claypole, T., & Gethin, D. (2015). Deposition of High Conductivity Low Silver Content Materials by Screen Printing. Coatings, 5(2), 172-185.

Malik, T., Malik, F., Clement, R., Gethin, D., Beysens, D., Cohen, R., Krawszik, W., Parker, A., Gethin, D., & Clement, M. (2015). Dew harvesting efficiency of four species of cacti. Bioinspiration & Biomimetics, 10(3), 036005