Our aerospace engineering facilities include a custom built £1.2million wind tunnel facility, provided by ATE Aerotech, which is used in aerodynamic research to study the effects of air moving past solid objects.

The wind tunnel is 18m long x 7m tall x 5m wide with a test section of 1.5m wide by 1m tall and can generate wind speeds up to 50m/s (112 mph).

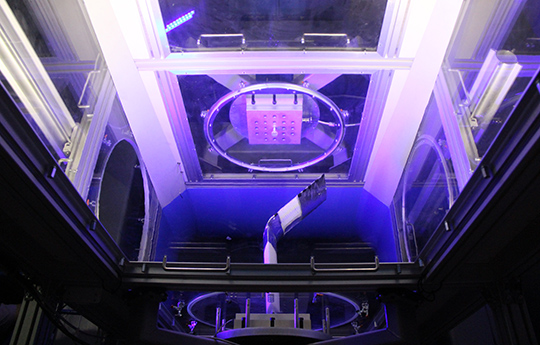

The wind tunnel includes a state-of-the-art Particle Image Velocimetry (PIV) system to measure fluid flow velocities in three dimensions, a high-precision three dimensional model deformation measurement system, and an automated turntable system for pitch and yaw angle sweeps.

The tunnel design is a closed section, closed circuit system which is more energy efficient, quieter, and more consistent in air speed and temperature. It also includes a novel, completely modular, transparent working section with high resolution balances and LED lighting which will allow for unparalleled access, visibility, and versatility.

This allows the facility to be used for a variety of different activities and experiments, including researching advanced 2D airfoils, 3D wings, model aeroplanes with working engines, wind turbine blade sections, and even small scale automotive testing over a wide range of flow conditions and Reynolds numbers.