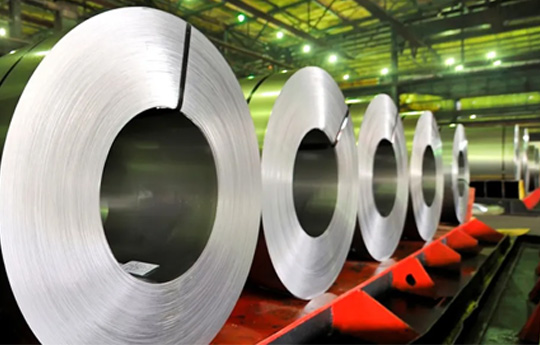

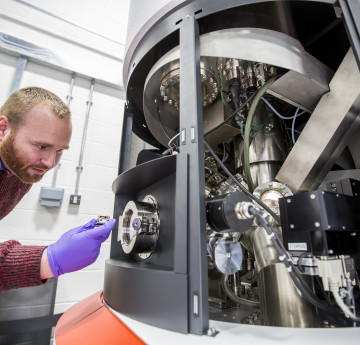

Swansea University was founded to help meet the needs of industry in a region famous for its expertise in metals. Today the University continues to work together with the steel industry in leading innovation.

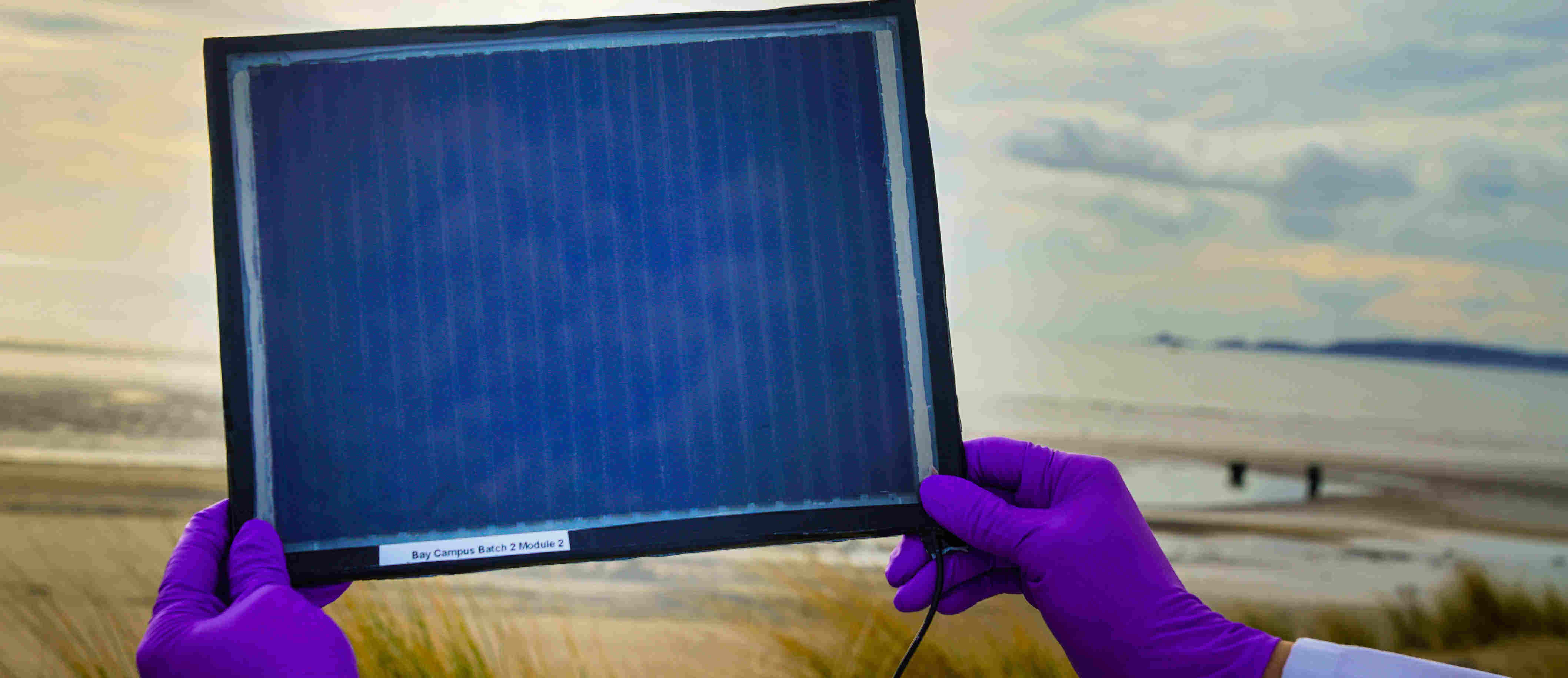

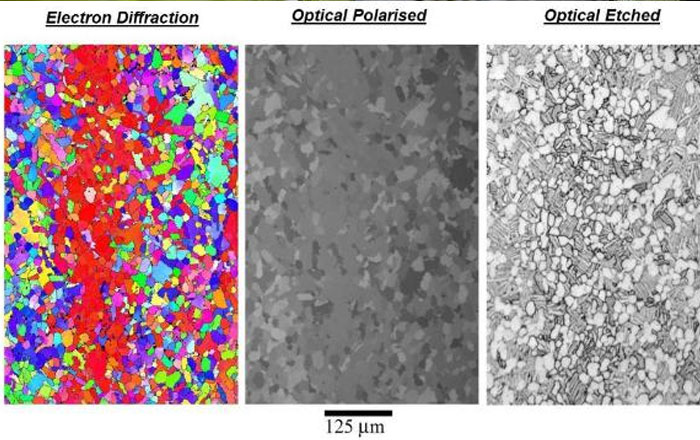

Steel is the backbone of today’s world, from buildings and bridges to food cans and fridges. But it’s also an industry of tomorrow. Steel can be recycled infinitely, with no loss of quality - it’s the world’s most recycled material. From high-speed rail and electric cars to solar technology and wind turbines, a cleaner, greener future depends on steel.

Swansea University researchers are leading this innovation, developing tomorrow’s technologies, such as more sustainable transport and buildings.