A Swansea University research team have launched a new digital platform that will transform the way supply chains operate within the manufacturing industry.

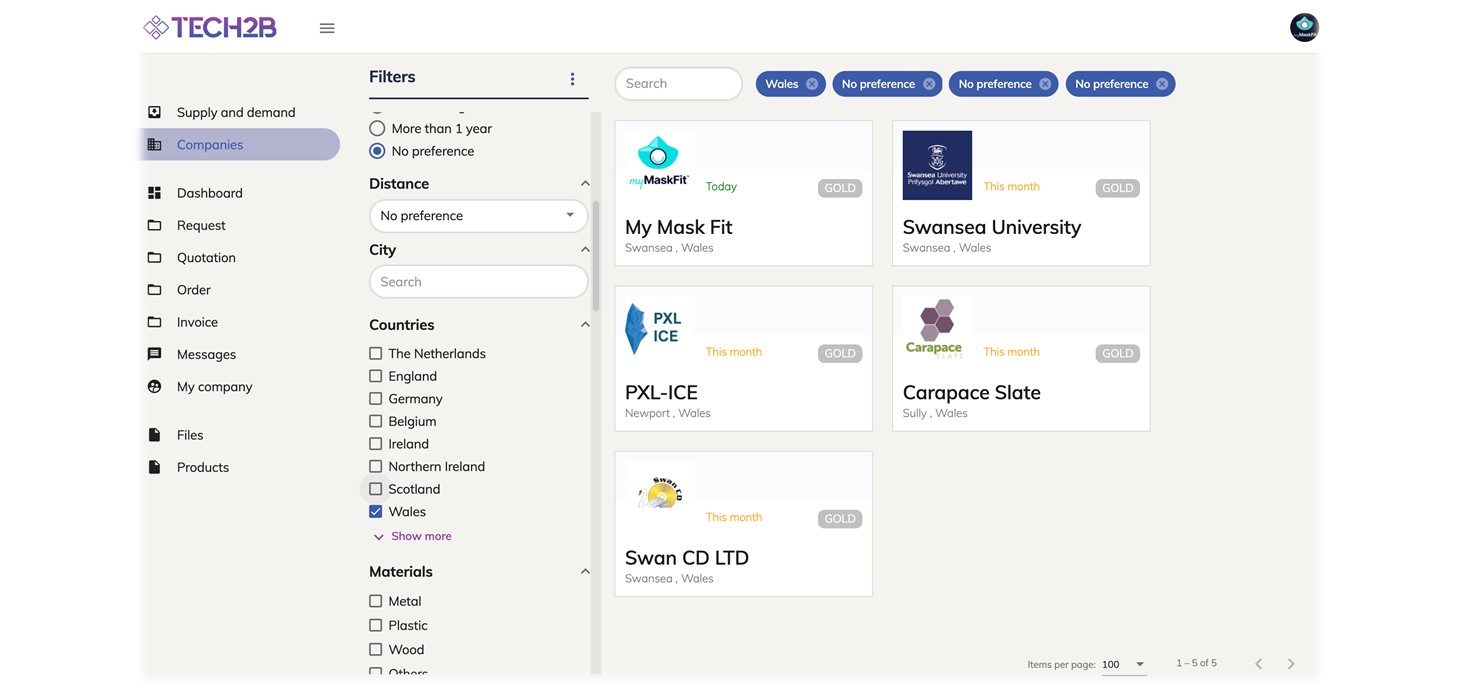

This innovative online system, supported by the Institute for Innovative Materials, Processing and Numerical Technologies (IMPACT), allows suppliers to register their products and services to become part of an approved network.

The marketplace will provide more transparency in the supply chain process with improved response times and accurately priced goods/service - providing reassurance on quality, cost and certainty.

Through better connected manufacturers and suppliers, companies can begin to see products brought to market at a quicker and more efficient rate.

A new face mask company, MyMaskFit, has been working with IMPACT on manufacturing, testing and bringing to market custom-fit face masks. The company are the first to trial the platform and are now about to enter the first stages of production.

Principle Investigator, Professor Johann Sienz, comments:

‘We are delighted to see the success the platform has brought to MyMaskFit. It has enabled the company to move their bespoke face masks forward at a faster pace – which is crucial at this current time.

The launch of the digital marketplace will greatly enhance manufacturing supply chain networks. It will provide access to a more open and dynamic market, with increased opportunity for UK SMEs, and by making markets more efficient and flexible, should raise productivity, competitiveness and open new value chains through wider reach.

Our aim was to create a new industry-wide business model that can be replicated nationally and globally – with this significant milestone we are one step closer to achieving this.’

MyMaskFit’s Technology Director and project lead, Paul Perera, comments:

‘The initial solution to have customised medical grade masks for the NHS and Social Care environment, which are designed to fit the face of the care worker who scans their face on the MyMaskFit application, is now ready to scale up. We have developed a customised seal which will fit between the hard transparent shell of the mask and the face with medical grade silicone, and the moulds to make these seals are made using Additive Manufacturing.’

‘This mass customisation approach leverages the Swansea University led Manufacturing Made Smarter Testbed to bring a volume production of these moulds and seals in a regulated marketplace. We have also been able to tap into the spare capacity of some of the largest manufacturing companies in Aerospace in the UK to support this marketplace and our scale up initiatives, and now are keen that smaller companies are also able to benefit from new demands and have access to the marketplace to create new supply chain networks.’

The platform is open and ready for registration – with customers currently being able to experience three months free of charge: madesmartermarketplace.co.uk

The research team developing the marketplace includes expertise from the Manufacturing Technology Centre (MTC) and WMG University of Warwick with industry partners Autodesk, Tech2B, Plyable, Carapace, PXL ICE, Cadarn and AI Idea Factory.

Asif Moghal, Design & Manufacturing Industry manager, EMEA at Autodesk added:

‘Systemic changes in the manufacturing industry were underway well before the widespread disruptions of 2020. But the last 12 months have shown the importance of converging digital and physical environments to enable agility and achieve incredible results.’

‘A digital marketplace could enable that kind of agile collaboration to become the new normal, delivering value to the industry, upskilling its workforce and implementing processes to reduce environmental impact. We’re delighted to be partnering with the team on this project.’

Sjors Hooijen - Co-Founder and Chief Technology Officer at Tech2B comments:

'The Tech2B platform was designed to prepare the continuously changing design and manufacturing industry for the future. A secure, cloud-based environment will enhance transparency, focus on process optimization and clear communication. The platform is a great tool, but in the end, it will be the companies on it that bring added value to one another by reducing failure costs, shortening time to market and bringing collaboration and joint innovation to a whole new level.'

Lynne McGregor, Senior Innovation Lead - Manufacturing Made Smarter and Innovation Hubs at UKRI, comments:

The project is funded by the Innovate UK, the UK’s innovation agency, Manufacturing Made Smarter funding programme. The IMPACT operation is part-funded by the European Regional Development Fund through the Welsh Government and Swansea University.