What we do

Pressure is increasing on our limited water resources. With more people requiring clean water, effective solutions need to come from reusing water in the most efficient way.

The Centre for Water Advanced Technologies and Environmental Research (CWATER) is an internationally leading centre of excellence for the development of advanced technologies in water treatment.

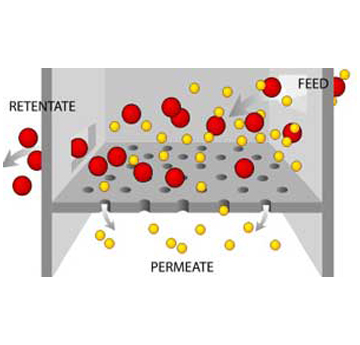

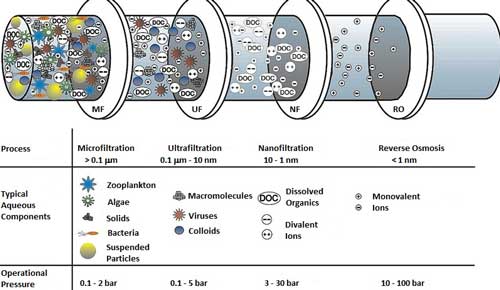

The Centre benefits from world-leading expertise in the areas of desalination and membrane technologies for water treatment.