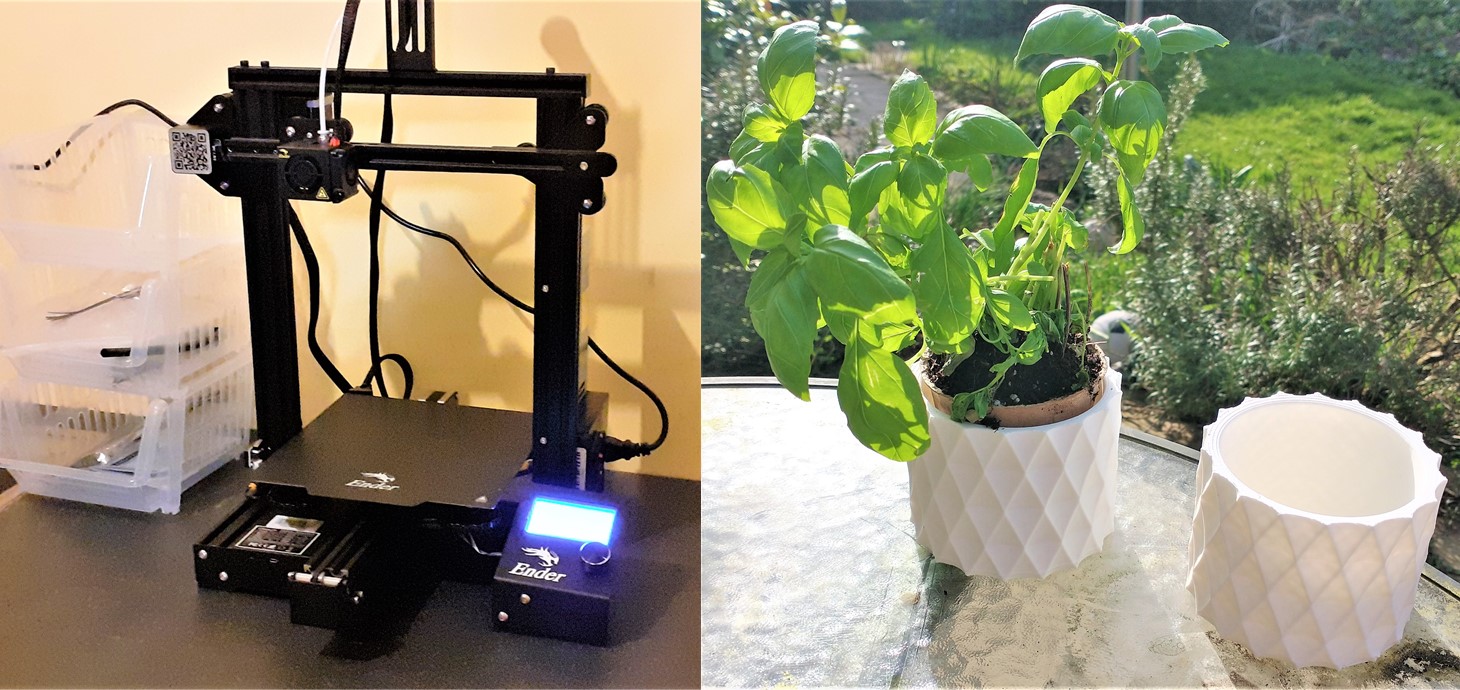

3D printer at home, with plant pots manufactured using it: students are getting vital hands-on experience of the machines at home

Engineering students have been getting vital hands-on experience, despite laboratories being off-limits due to COVID, thanks to home lab kits developed and sent out by their lecturers.

Working and problem-solving with physical parts and machinery is a crucial part of engineers’ training. However, social distancing and then a switch to online teaching has made it impossible for them to do this in the labs on campus.

Thanks to some creative thinking by lecturers at the College of Engineering, the students are not missing out: the students can’t go to the lab, so the team has taken the lab to the students, sending them equipment they can use at home.

Engineering students on two different modules are already benefitting.

70 Students on the digital manufacturing module were each sent a loan 3D printer at the start of semester 2. It meant that they have been able to get vital practice with the technology, build their own parts, and produce the work needed to complete their module. The students have also been able to keep the machines and continue their learning at home over the summer to support their future studies in year 3.

Dr Peter Dorrington, senior lecturer in the College of Engineering, said:

“Typically we have 70 students, in three parallel labs building machines. Working with Create Education we found suitable machines and – despite delays due to Brexit and Covid – we were able to send them out to our students, both in the UK and as far afield as Spain, Hong Kong and Dubai.

This commitment is to ensure our students get ‘hands-on’ engineering experience: ’physicality’ is an essential part of learning for engineers.

We’re very excited to have the support of Associate Prof. Eifion Jewell, Prof. Cris Arnold and Ruth Bunting to make this happen.”

Mark McCall, a student who has been learning at home on one of the 3D printers, said:

“I’ve really enjoyed the printing module as it’s been very experimental and hands on. You learn to do it better by playing around with settings or different types of models which is a lot of fun!”

Another group of students to benefit are those on a module called Data Integration in Mechanical Systems.

Tutors have made 250 kits for students, consisting of a programmable micro controller, a sensor and some connecting leads. Each student either collected their kit or received it through the post. They were then asked to devise an experiment where they could demonstrate what they had learnt about data capture through digital sensors and data analysis.

The kits cost £15-20 each and were designed to link with the learning outcomes for the module.

Dr Eifion Jewell, associate professor in the College of Engineering, said:

“With a cohort of around 220, it was unfeasible to bringing the students to the lab, so the lab had to go to the students.

This approach not only allowed us to put hardware in students’ hands but also gave an opportunity for students to apply the technology in the real world. This led to a wide range of highly novel experiments which were way beyond anything that we would have attempted in the lab. We will be using the same methodology next year, pandemic or not!”